Products

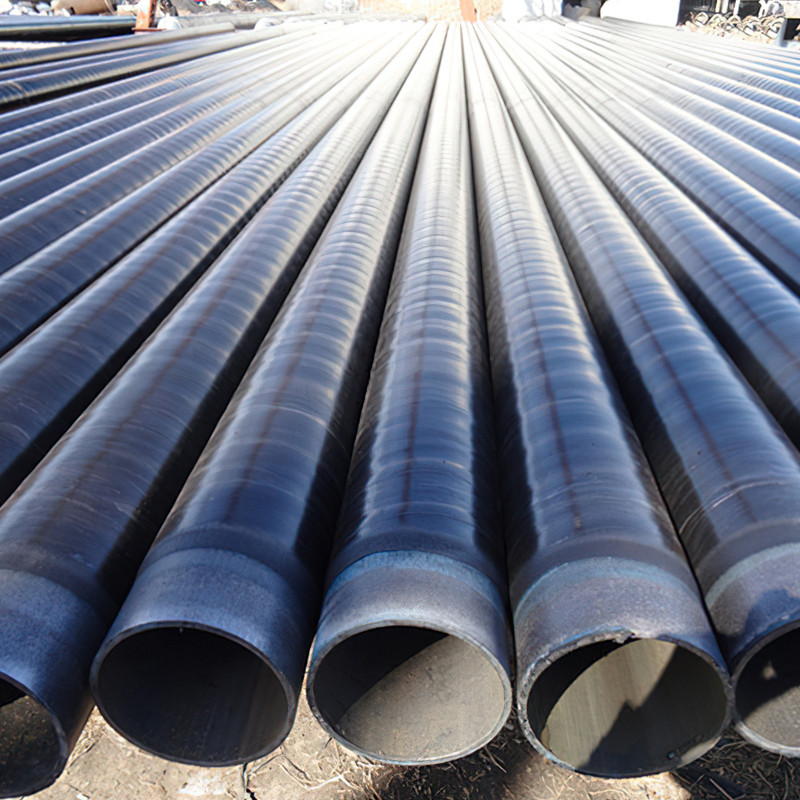

China Cheap price Galvanized Steel Pipe - ANTI-CORROSION PIPE-3LPE/PP/FBE – Sinoworld

China Cheap price Galvanized Steel Pipe - ANTI-CORROSION PIPE-3LPE/PP/FBE – Sinoworld Detail:

Application

The external coating is mainly used for anti-corrosion protection for liquid pipes before burying, and internal drag-reducing coating is mainly used to reduce the investment and maintenance costs Outer Corrosion Protection of Steel Pipes:

1.Single-layer FBE Coating

Characterized by excellent corrosion-proof performance,insulatibity and relatively long service life,epoxy powder coating is one of the most advanced outer anticorrosive coating of pipeline.There are normal type and strengthened type.Thickness:normal type:300~400um;strengthened type:400~500um.

2.Two-layer FBE Coating

Two-layer epoxy powder coating is a compound coating struture composed of anticorrosive epoxy powder floor layer and mechanical damage resistant epoxy powder surface layer.There are normal type and strengthened

type.thickness;Total Thickness of normal type≥620um;Total Thickness of strengthened type≥800um.

3.Two-layer PE/PP coating

Two-layer PE/PP coating is characterized by excellent corrosion-proof performance,insulatibity,relatively long service life and mechanical damage resistance.There are normal type and strengthened type.The thickness varies with the specification shift of steel pipe:thickness Min of Normal Type:1.8mm:Thickness Min of Strenthened type:2.5mm.

4.Three-layer PE/PP coating

Three-layer PE/PP coating is characterized by excellent corrosion-proof performance,insulatibity,relatively long service life and mechanical damage resistance.It is widely used in coating for all kinds of major pipeline engineering.There are normal type and strengthened type.The thickness varies with the specification shift of steel pipe:thickness Min of Normal .

Type:1.8mm:Thickness Min of Strenthened type:2.5mm

Inner Corrosion Protection of Steel Pipes:

We offer inside corrosion protection for DN100~700mm steel pipes.We coat inner wall of treated steel pipe with red oxide anticorrosive paint ,bicomponent liquid epoxy paint or other paint designated by clients by means of Centrifugal coating

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our organization has strived to establish a highly efficient and stable employees team and explored an effective high-quality command method for China Cheap price Galvanized Steel Pipe - ANTI-CORROSION PIPE-3LPE/PP/FBE – Sinoworld , The product will supply to all over the world, such as: Bandung, Burundi, azerbaijan, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.