Products

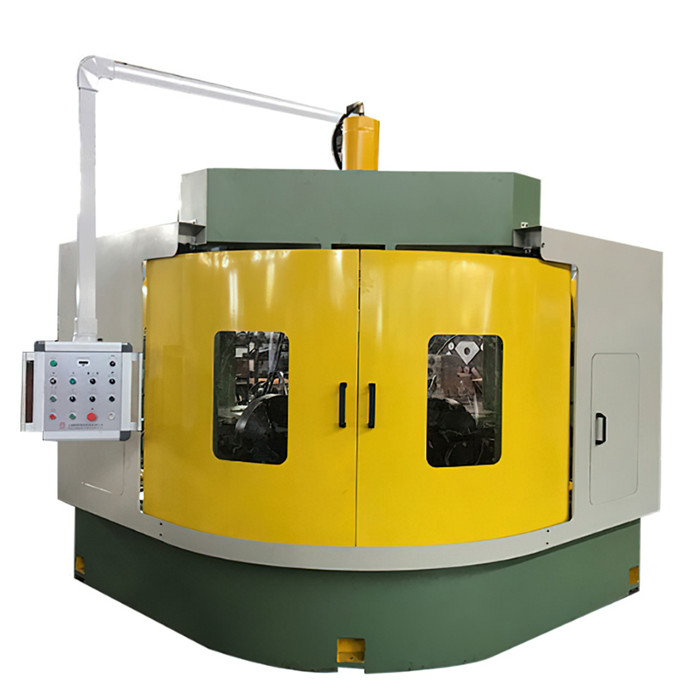

China wholesale Cold Forming Elbow Machine - bevelling machine – Sinoworld

China wholesale Cold Forming Elbow Machine - bevelling machine – Sinoworld Detail:

Q1245 beveling machine

| SerialNo. | Name | Parameter value | Unit | Remark | |

| 1 | Power unit | Moter power | 4 | KW | Main motor |

| Spindle speed | 960 | R/min | |||

| Tool carrier differential feeding quantity | 0,0.17 | Mm/r | |||

| Tool manual axial direction strokes |

200 | mm | |||

| manual axial direction speed | 18.8 | Mm/r | |||

| 3 | Clampplatformorgan | Clamping type | hydraulic | ||

| 4 | Cutterhead organ |

Cutterhead diameter | Φ550 | mm | |

| Angle tool carrier | 0-35° | Differential progressing | |||

| Cutterhead speed | 54-206 | rpm | Six gears | ||

| Cutting diameter | Φ30-φ426 | mm | |||

| cutting thickness | 6-100 | mm | |||

| Groove type | Single V,double U V | Or decided by tool | |||

| 6 | Lathe outline | Spindle central height | 1000 | mm | |

| Lathe weight | 2000 | kg | |||

The chamfering machine is a special tool for chamfering and beveling pipes or plates on the welding front face. The chamfering machine solves the shortcomings of irregular angles, rough slopes, and large working noises in flame cutting, grinder grinding and other operating processes. It has the advantages of easy operation, standard angle and smooth surface.

Before starting, check whether the protective cover is intact and fastened; whether the tool movement direction and the table feed direction are correct.

The use of fast machine chamfering is the development trend of the machinery industry. It overcomes the processing shortcomings of existing machinery and electric tools, and has the advantages of convenience, speed and accuracy. It is the best choice for chamfering of metal objects at present.

Product detail pictures:

Related Product Guide:

It can be our accountability to satisfy your preferences and competently provide you. Your satisfaction is our greatest reward. We are searching ahead towards your visit for joint growth for China wholesale Cold Forming Elbow Machine - bevelling machine – Sinoworld , The product will supply to all over the world, such as: Nairobi, Malaysia, Tajikistan, Now we have a dedicated and aggressive sales team, and many branches, catering to our main customers. We have been looking for long-term business partnerships, and ensure our suppliers that they will undoubtedly benefit in both short and long run.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.