Products

China wholesale Cold Forming Tee Machine - cold forming tee making machine – Sinoworld

China wholesale Cold Forming Tee Machine - cold forming tee making machine – Sinoworld Detail:

Mode NO: GIL114

Size range:OD17-114 Thickness:max8mm

Ram Cylinder:

| Piston | Ram | Cylinder | Valid Travel | Working Pres. | Qty |

| Φ400mm | Φ280mm | Φ490mm | 400mm | 32MPa | 1 |

| Φ380mm | Φ250mm | Φ470mm | 300mm | 32MPa | 2 |

Other Parts

|

2grade oil pumper |

63SCY-14 | QTY | 1pc |

| CB-32 | QTY | 1pc | |

|

Electric Engine |

Y-18.5KW | QTY | 1pc |

| Y-7.5KW | QTY | 1pc |

Work capacity of the machine: 455kgs/hour

Power need per ton: 30kw

Dimension: L*W*H: 2700mm*800mm*2700mm

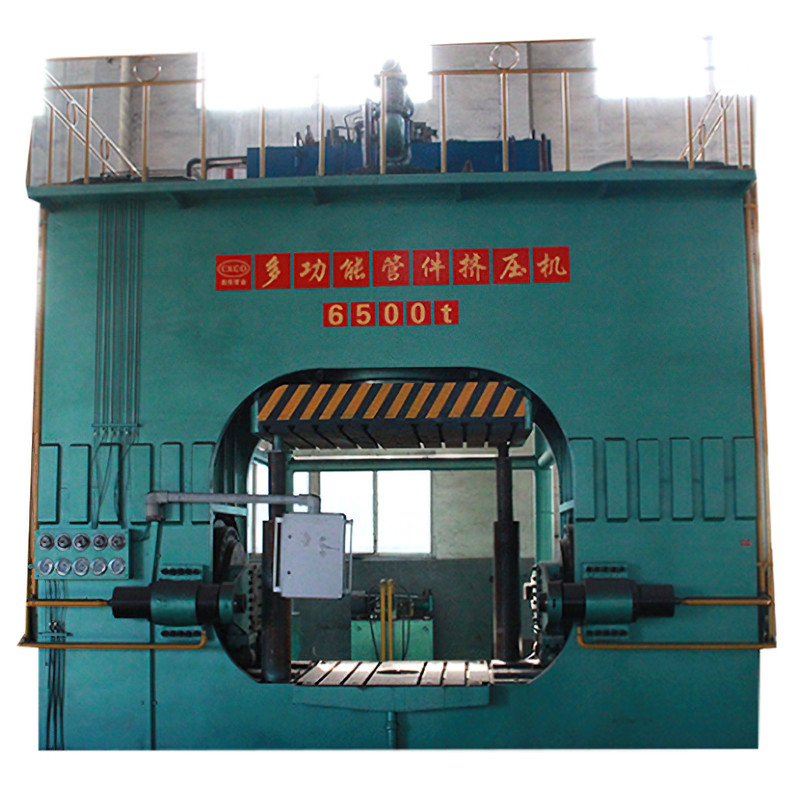

Cold Forming Tee making Machine is designed for manufacturing both straight tees and reducing tees with diameter from 1/2″ to 28″ of stainless steel, carbon steel, alloy steel and some kinds of copper steel. Complying with standards of ASME B16.9, ASMB16.11,GB12459,JIS, DIN and GOST, the products are wildly used in industries of sanitary, oil and gas delivery pipeline and nuclear or power plant construction etc.

Main features

* Integrated welding frame after heat treatment for stress relieving.

* The cold forming parameters (forming speed, pressure and cycle time) can be set in the PLC system based on raw pipe size by touch screen .

* Advanced logical circuit hydraulic system design with servo motor and proportional valve. It can adjust oil flow and internal fluid forming pressure automatically.

* Adopt micro pulse displacement transducer to assure best synchronization precision and minimum tolerance.

* Servo motor is used for saving electric consumption and achievinglower noise.

* Three kinds of operation modes: manual, semi-automatic and automatic

* The machine can produce 2 pieces of T fittings in one forming cycle time for small size.

* The machine capacity (T fittings size, thickness) can be customized as per client’sspecial

* CE approved and ISO 9001: 2015certified.

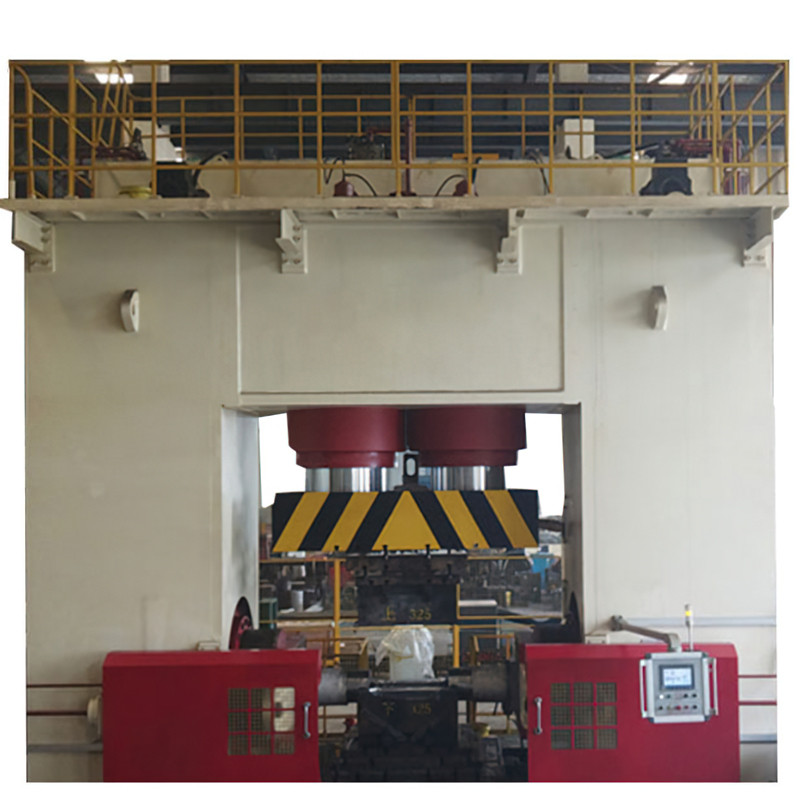

Product detail pictures:

Related Product Guide:

We keep improving and perfecting our products and service. At the same time, we work actively to do research and development for China wholesale Cold Forming Tee Machine - cold forming tee making machine – Sinoworld , The product will supply to all over the world, such as: Peru, US, European, We offer OEM services and replacement parts to meet the varying needs of our customers. We offer competitive price for quality products and we will make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.