Products

Chinese Professional Spiral Steel Pipes - Low Temperature Pipe (A333 A334 Gr.6 Gr.3) – Sinoworld

Chinese Professional Spiral Steel Pipes - Low Temperature Pipe (A333 A334 Gr.6 Gr.3) – Sinoworld Detail:

Mainly Grade

Grade 1, Grade 3, Grade 4, Grade 6, Grade 7, Grade 8, Grade 9, Grade 10, Grade 11;

Low temperature carbon steel pipe quenching temperature in A3 + (30 ~ 50) ℃, in practice, is usually set to the upper limit. High quenching temperature heat pipe can make low speed, surface oxidation reduction, and can improve work efficiency. The workpiece is uniform austenite, will require sufficient holding time. If the actual installed furnace capacity, would need to be appropriate to extend the holding time. Otherwise, there may be insufficient hardness due to uneven heating caused by the phenomenon. However, the holding time is too long, will also appear coarse grains, oxidation and decarbonization serious ills affecting quenching quality. We believe that if installed furnace is greater than the process documents, heating holding time to be extended 1/5.

Low temperature carbon steel pipe because of low hardenability, it should adopt a large cooling rate of 10% salt solution. Workpiece into the water, should hardenability, but not chilled, if 45 # precision steel chilled in brine, it is possible cracking of the workpiece, this is because when the workpiece is cooled to about 180 ℃, the austenite rapidly converted to horse s body tissue caused by excessive stress due. Therefore, when the quenching and tempering steel quickly cooled to this temperature range, the approach should be taken to slow cooling.

As the water temperature is difficult to grasp, accountable experience in operation, when the water stops dithering artifacts, you can water cooled (eg oil cooler can be better). In addition, the workpiece into the water, appropriate action should still be in accordance with the geometry of the workpiece, as regular exercise. Stationary cooling medium plus stationary workpiece, resulting in uneven hardness, stress uneven leaving large deformation of the workpiece, and even cracking.

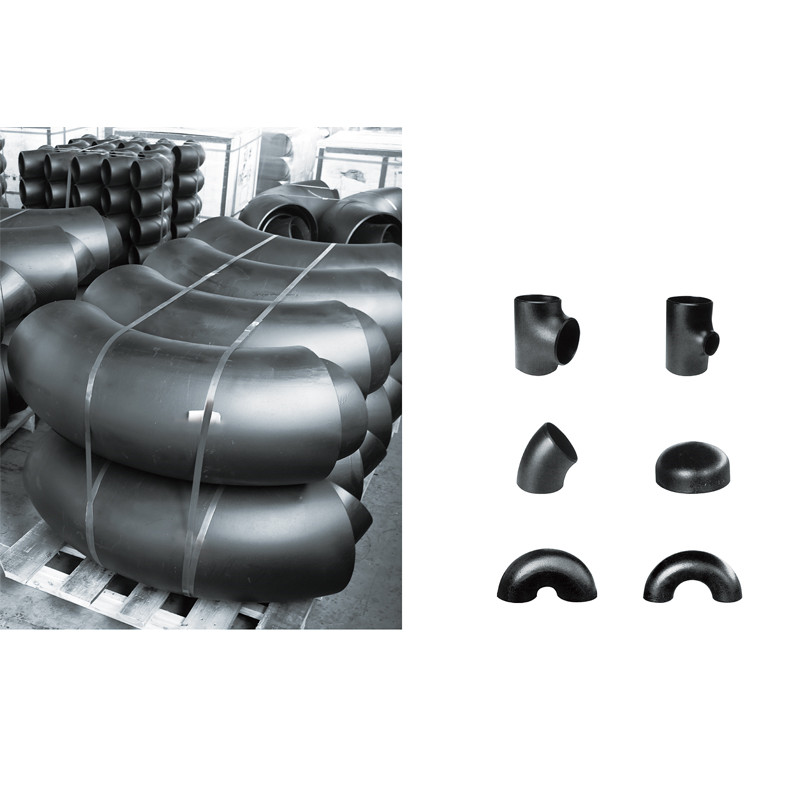

Product detail pictures:

Related Product Guide:

As a way to provide you advantage and enlarge our organization, we even have inspectors in QC Crew and guarantee you our greatest assistance and product or service for Chinese Professional Spiral Steel Pipes - Low Temperature Pipe (A333 A334 Gr.6 Gr.3) – Sinoworld , The product will supply to all over the world, such as: United Arab Emirates, Danish, azerbaijan, We'll initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.