Products

OEM/ODM Factory Galvanized Blind Flange - Fittings (Tee Elbow Caps Reducer) – Sinoworld

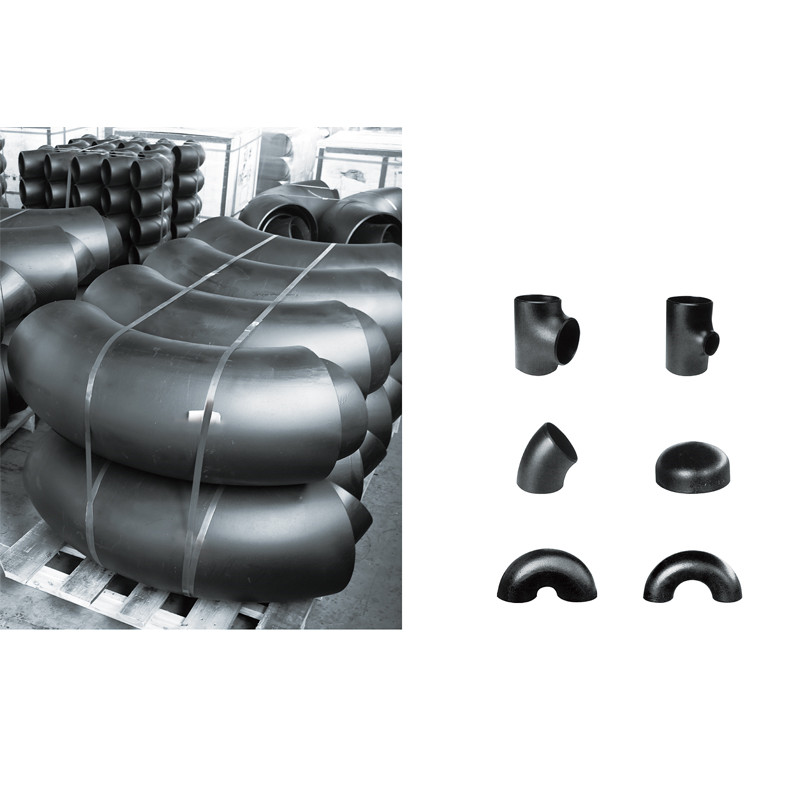

OEM/ODM Factory Galvanized Blind Flange - Fittings (Tee Elbow Caps Reducer) – Sinoworld Detail:

Elbow In the pipeline system, the elbow is a pipe fitting that changes the direction of the pipeline. According to the angle, there are three kinds of 45° and 90°180° which are more commonly used. In addition, according to engineering needs, it also includes other abnormal angle elbows such as 60°. The elbow materials are cast iron, stainless steel, alloy steel, malleable cast iron, carbon steel, non-ferrous metals and plastics. Do you know what its technical requirements are? Follow the editor of Elbow for Power Engineering to learn more about it!

1. Since most of the pipe fittings are used for welding, in order to improve the welding quality, the ends are beveled, with a certain angle and a certain side. This requirement is also strict, how thick the side, how much angle and deviation The scope is stipulated. The surface quality and mechanical properties are basically the same as the pipe. For the convenience of welding, the steel grade of the pipe fitting and the pipe being connected is the same.

2. That is, all pipe fittings must be surface treated, and the iron oxide scale on the inner and outer surfaces is sprayed off by shot blasting, and then coated with anticorrosive paint. This is for export needs. Moreover, it is also for the convenience of transportation in the country to prevent corrosion and oxidation. This work must be done.

3. It is the requirements for packaging. For small pipe fittings, such as export, it is necessary to make wooden boxes, about 1 cubic meter, and the number of elbows in this box cannot exceed one ton. The standard allows sets, that is, large sets and small sets. But the total weight generally cannot exceed 1 ton. For large items, single packaging is required, such as 24″ must be individually packaged. The other is the packaging mark, which must indicate the size, steel number, batch number, manufacturer’s trademark, etc.

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected pleasure , we have now our solid crew to supply our greatest all round assistance which includes marketing, sales, planning, production, top quality controlling, packing, warehousing and logistics for OEM/ODM Factory Galvanized Blind Flange - Fittings (Tee Elbow Caps Reducer) – Sinoworld , The product will supply to all over the world, such as: Borussia Dortmund, Macedonia, Oslo, We have now 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export solutions to other countries. We expect to cooperate with you to develop a larger market.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.