Products

Professional China Bevelling Machine – cold forming elbow machine – Sinoworld

Professional China Bevelling Machine – cold forming elbow machine – Sinoworld Detail:

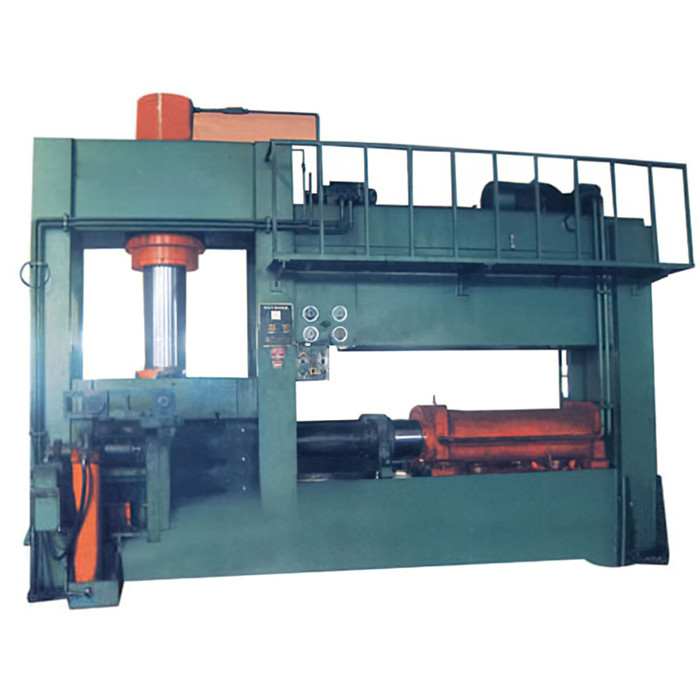

Product name:High Quality Cold Forming Elbow Machine

Condition:New

Type:cold Forming Ebow Machine, hydraulic cold forming

Pipe Material:CS SS Alloy Stainless Steel

Application:Energy Supply Pipe

Voltage:380v

Power:30KW

Dimension(L*W*H):5800X3200X4700

Weight:2500kg

Technical details

|

TYPE PARAMETER |

ZTW-219~325 |

|

PRODUCTION CAPACITY(mm) |

Ø 219-Ø325 |

|

THICKNESS(mm) |

3~20 |

|

LIQUID WOEKING PRESSURE(MPa) |

25 |

|

LOCKING NOMINAL PRESSURE(KN) |

6300 |

|

LOCKING MAX TRAVELLING DISTANCE (mm) |

1360 |

|

PUSHING NOMINAL PRESSURE(KN) |

3150 |

|

PUSHING MAX TRAVELLING DISTANCE(mm) |

1330 |

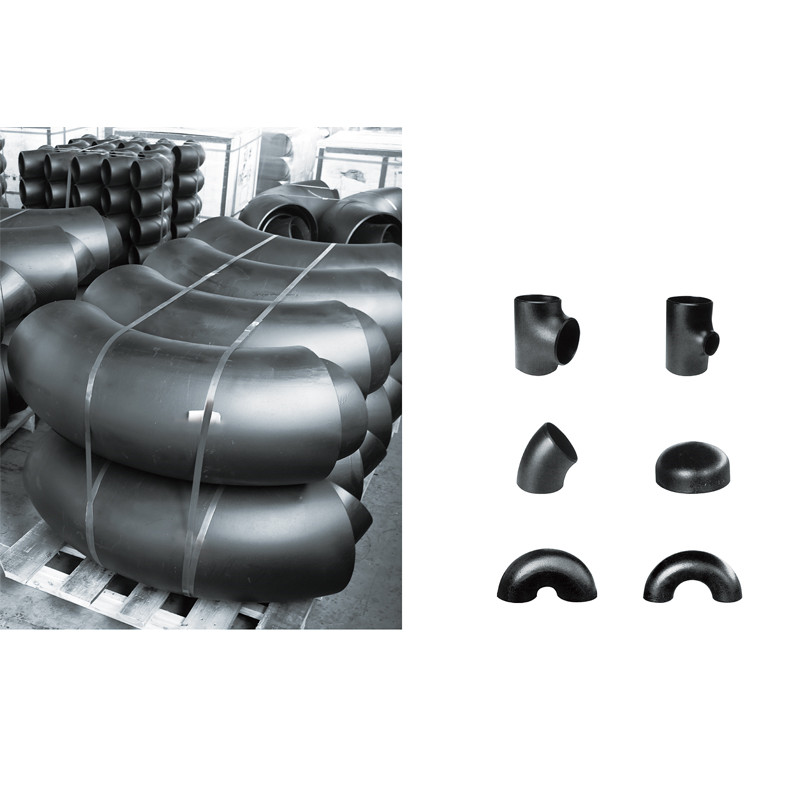

Cold Forming Elbow Machine is designed for manufacturing 90 &45 degree R=1.0D & R=1.5D elbows with diameter from 1/2″to 32″ of stainless steel, carbon steel, alloy steel and some kind of copper steel. Complying with standards of ASME B16.9, ASMEB16.11,GB12459,JIS, DIN and GOST, the products are wildly used in industries of Petrochemical, Oil and Gas pipeline, Power Plant,Metallurgy, and Foods etc.

Main Features

Two kinds of frame design: integrated frame and four column type. Making heat treatment for machine body to release welding stress.

* The proportional logical circuit hydraulic system running with servo motor makes the machines energy saving, low noise, stable operation and long life span.

* Application of PLC with touch screen realizes storing cold forming parameters (forming speed, pressure and cycle time etc) in the centralized PLC system by touch screen. Human- computer interface makes operation very easy.

* Three kinds of working modes including manual, semi-automatic and automatic, which can be exchanged easily.

* Electricaland hydraulic system use high quality spares parts which are imported from Germany, Japan, Italy and Taiwan to ensure best running performance.

* Special designed molds location devices realize more convenient molds assembly. It saves lot of time and labor cost on molds and mandrels.

* Elbow can be formed in one time, shape calibration will be no need. Suitable for mass production with highest efficiency.

* The hydro-forming elbow machines have protective fence and the safety interlock to ensure the operation safety. The machinecan be monitored automatically to ensure safety work.

* The special structure of the pushing heads and pushing rods are designed according to different processing sizes and wall thicknesses, which ensures the qualified ratio and high precision.

* Oil cooling system ensures long time running every day.

Product detail pictures:

Related Product Guide:

We have been proud from the higher consumer gratification and wide acceptance due to our persistent pursuit of high quality both on product or service and service for Professional China Bevelling Machine – cold forming elbow machine – Sinoworld , The product will supply to all over the world, such as: Canada, Cologne, Estonia, Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work whole-heartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.